The word calculator normally conjures up the image of a small box of electronics with an LCD screen and number pad. The sort of thing most people born after 1970 would have used at school or in the office to do calculations, before smart phones made them mostly obsolete. Before the invention of electronics calculators there was another type of machine used for arithmetic, the mechanical calculator.

From an early age I have been fascinated by mechanical and clockwork machines, probably stemming from taking apart old mechanical boiler time clocks that my dad would bring home from work, so when I spotting a mechanical calculator for sale on eBay I decided to bid on it so I could see up close how they work.

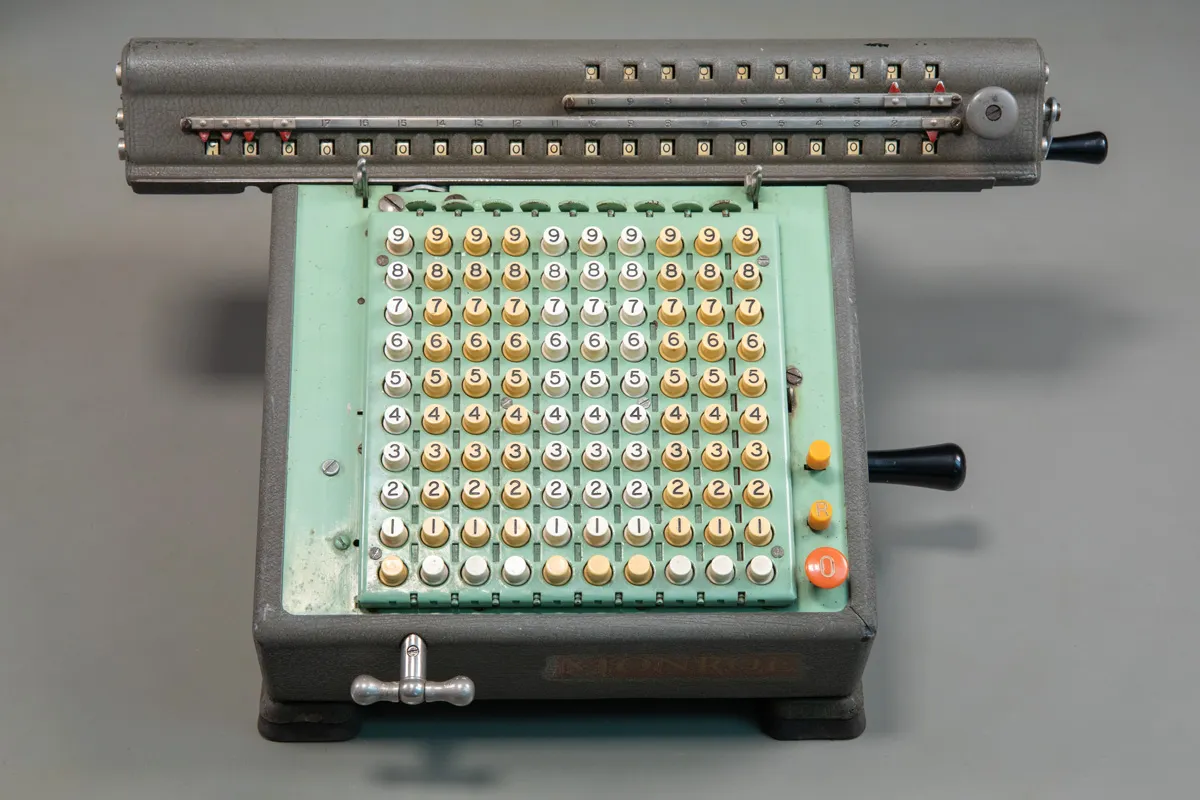

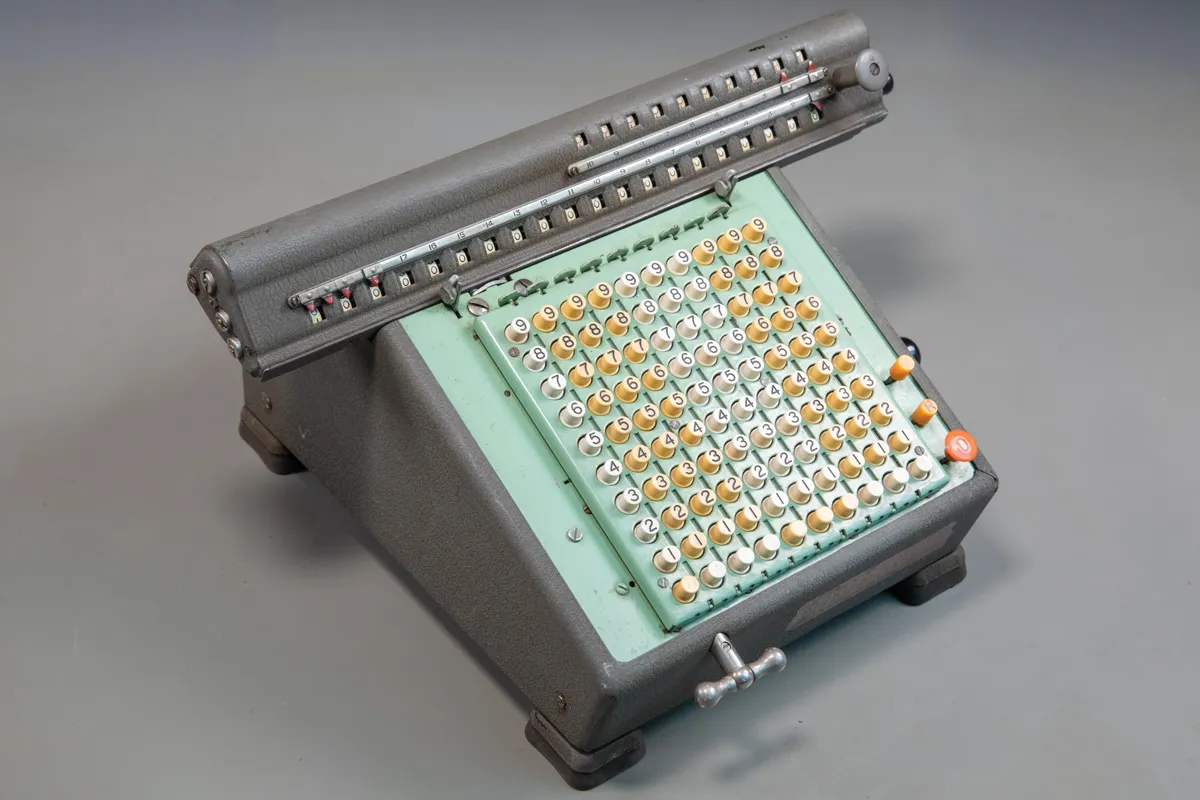

Monroe L-200X

The calculator I purchased is a Monroe model L-200X machine. The photos in the eBay listing showed some wear and tear that you would expect from a machine that is at least 60 years old but it looked mechanically sound with no big dents or missing parts. The machine arrived with the top movable carriage stuck and the reset handle would not rotate in either direction. The side crank handle was also buckled and would not turn. Clearly it would need some repairs before I could use it.

Monroe L-200X Crank Handle

Monroe L-200X Rear View

Design and Build Quality

The Monroe Calculating Machine Company was founded in 1912 and produced a range of mechanical calculators before moving on to electromechanical and electronic calculators. The company still exists today as Monroe Systems for Business.

The Monroe model L-200X was produced in 1940 and is a stepped gear machine with a full keyboard of 8 columns of numbers, a 16-decade total and an 8-decade counter. It has a heavy, industrial build, constructed almost entirely from metal, and was clearly built to withstand years of daily use.

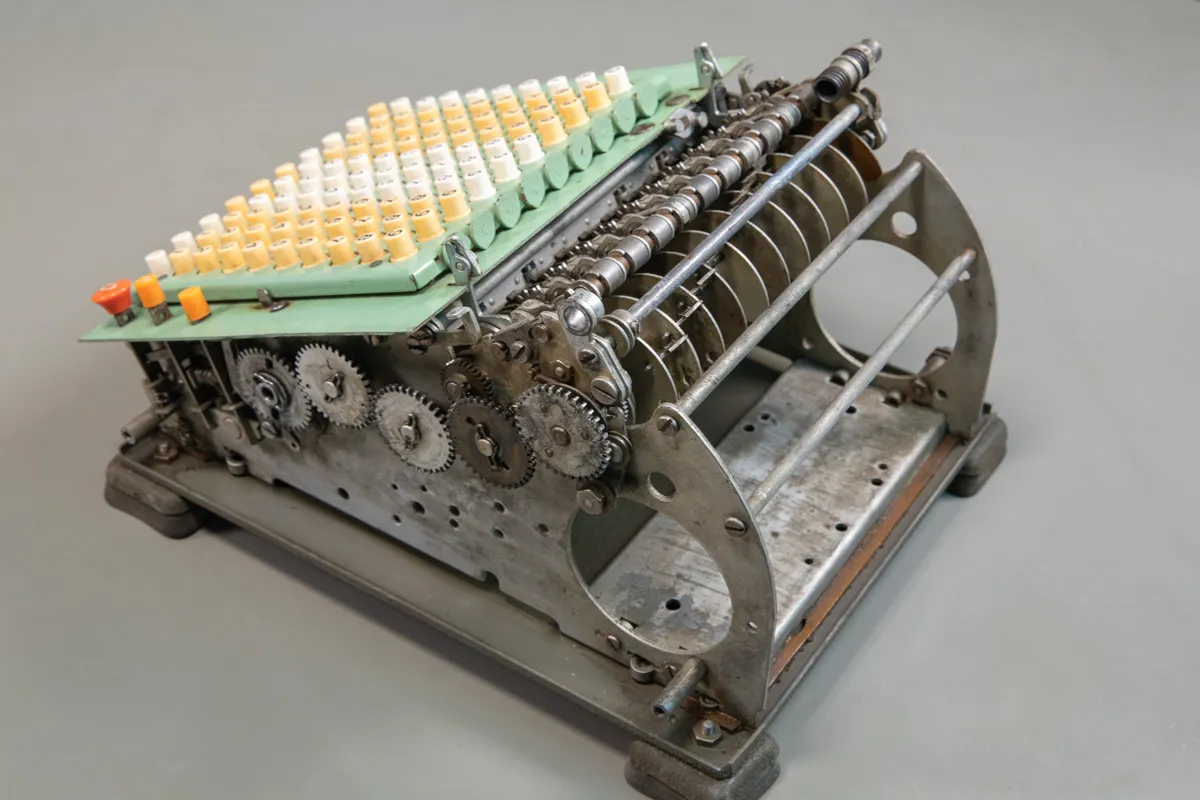

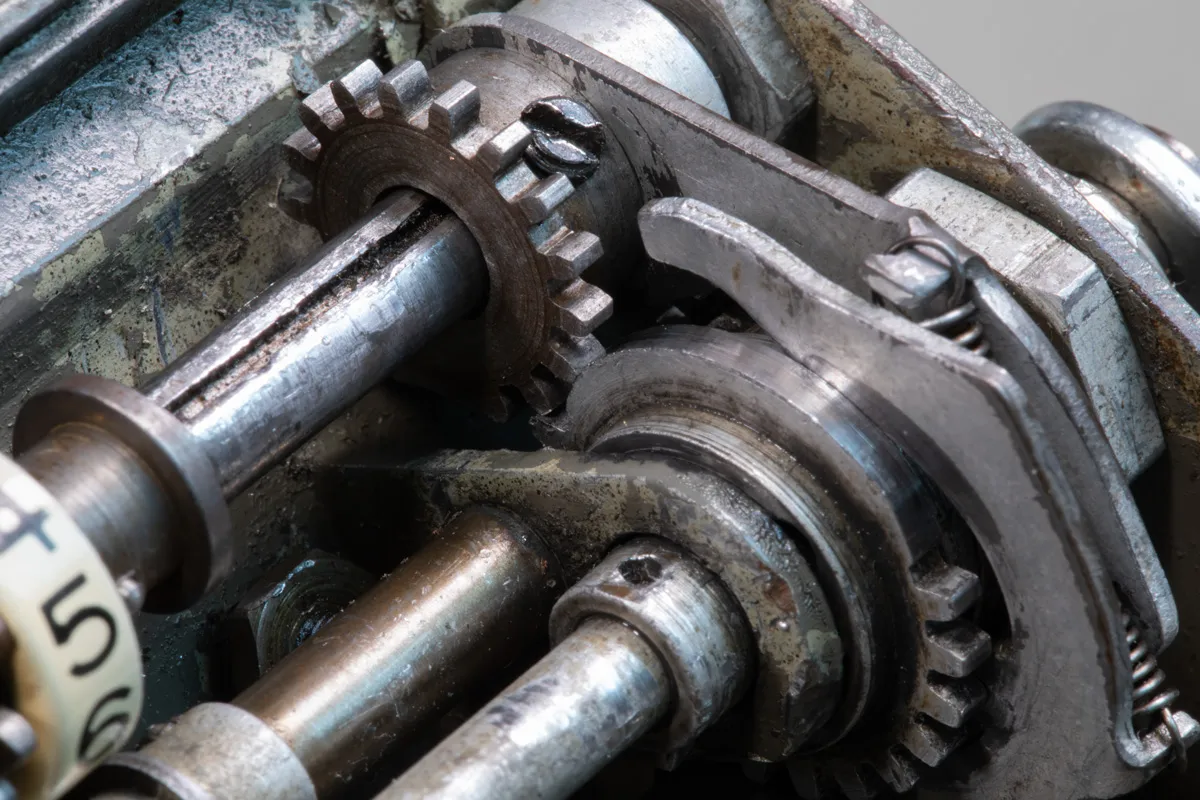

Each key and lever is mechanically linked to an intricate system of gears, springs, and ratchets hidden beneath the metal cover. This internal mechanism translates every key press into precise rotational movements, allowing the user to perform addition, subtraction, multiplication, and division, all without a single electronic component.

How the Monroe L-200X Calculator Works

While modern calculators rely on microchips and electricity, the Monroe L-200X operated entirely through mechanical logic. Every key press or lever pull physically moved parts within the machine, performing calculations that are displayed on a row of rotary dials at the top of the machine.

Cover Removed

The internal mechanism

The drive mechanism

Here’s how its main functions worked:

Addition and Subtraction

When the user entered a number and pulled the operating lever, the calculators numbered drums and gears turned to add or subtract the input value. The mechanism automatically carried or borrowed between digits, mimicking human arithmetic but at a far faster pace.

Multiplication

The calculator achieved multiplication through repeated addition. The user entered one number, then used the carriage lever to shift and repeat the process for each digit of the multiplier , much like performing long multiplication manually, but entirely automated through gears and motion.

Division

Division was the reverse process, achieved through repeated subtraction. The calculator mechanism would continuously subtract the divisor from the dividend while counting how many times it could do so, producing both the quotient and remainder mechanically.

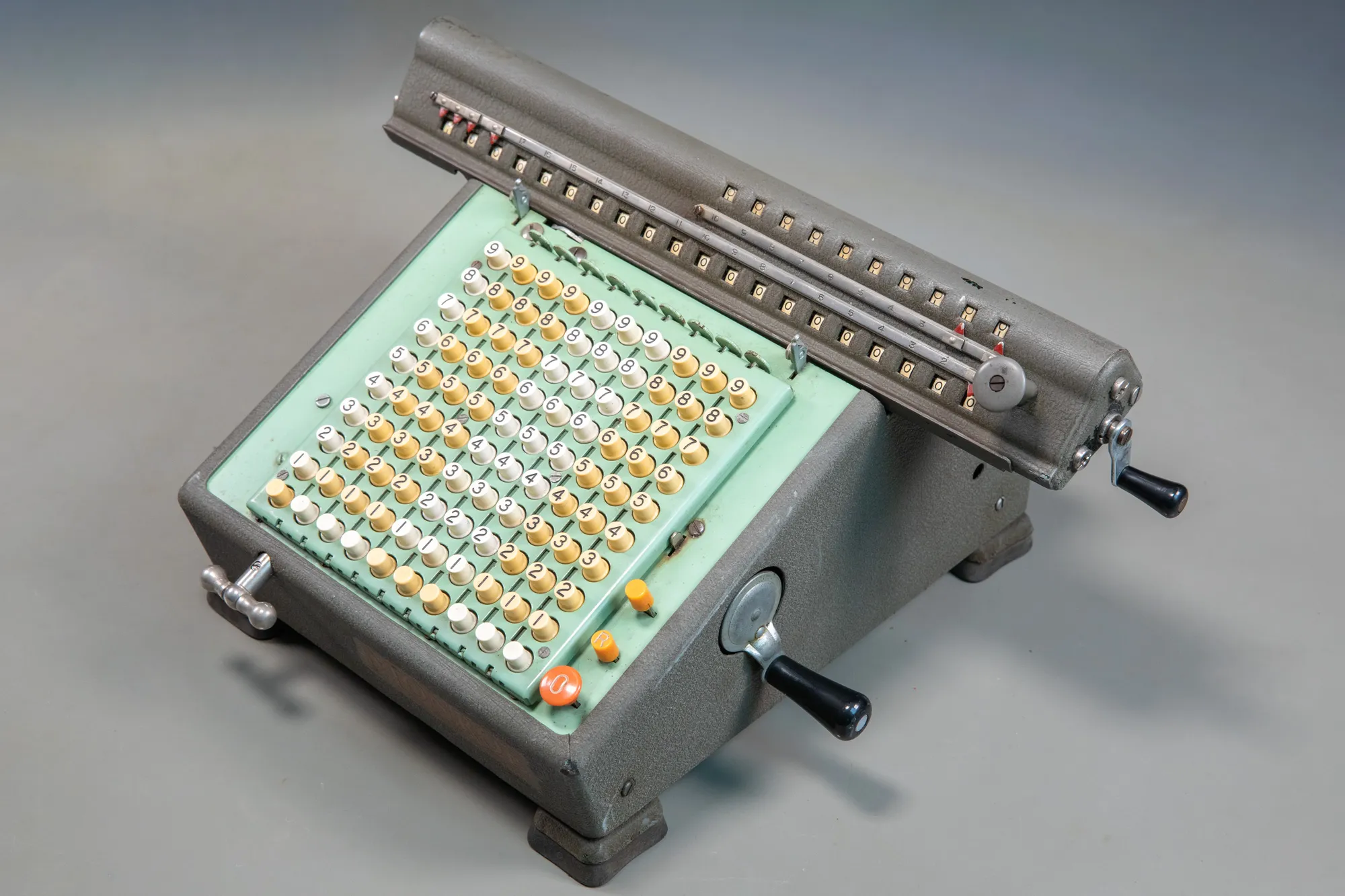

The Movable Carriage

The L-200X has a movable carriage, which is shifted by a rotational handle on the front of the machine during multi-digit operations. The digits are reset by turning the reset handle clockwise to reset the 8 digit counter and counter-clockwise to reset the 16 digit total row. The carriage can also be moved by lifting it and manually pulling it across the top of the machine.

Fractional Numbers

Instead of a decimal point, like you would find on modern calculators, the L-200X has two methods for showing the decimal location in a number. On the display carriage there are two rows of red arrows that can be slid across the carriage to different positions. The arrows can be used to show the location of the decimal point of divide the number up into sections, for example to show thousands and millions.

On the top of the keypad there are a row of dials between the columns of numbers. Rotating these dials 90 degrees will show a red line in the gaps between the columns. This can be used as a way of showing where the decimal point would be in the number.

Cleaning the calculator

Before any repairs could be attempted on the calculator it would need to be cleaned. The outer case and buttons were very dirty, with several decades of dust and grease from peoples fingers, so I cleaned these using isopropyl alcohol on cotton swabs.

Both the movable carriage reset handle and main function handle had been damaged and bent into the main metal frames so these where removed and straightened.

The outer cover was removed revealing a lot of dirt and dried out grease and oil residue. This was cleaned and a light oil was added to the gears in the machine.

Button Rotors

With the main handle reinstalled, I was able to turn the handle and the main mechanism turned freely but the reset mechanism and counters in the movable carriage would not turn so I could not see the resulting calculations.

Movable carriage cleaning and repair attempt

We removed the movable carriage and found that it was full of dirt and old grease which was cleaned using a degreasing solvent.

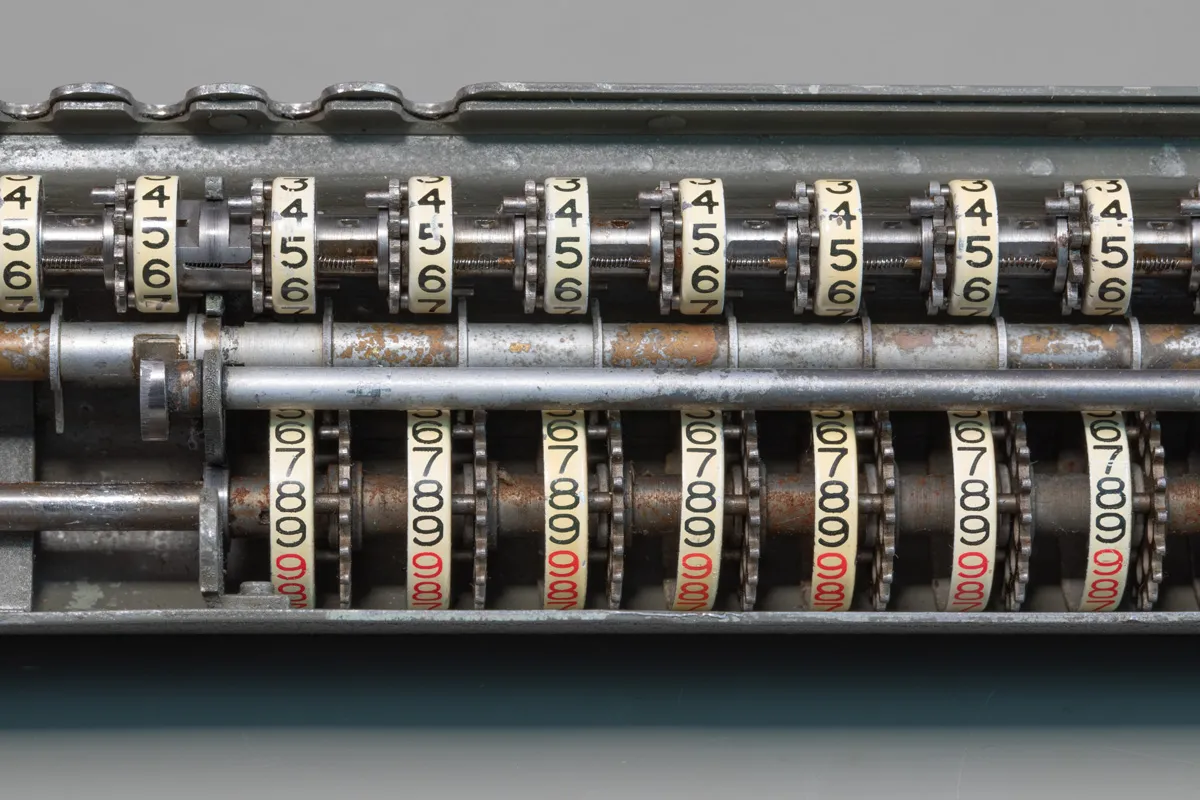

Display Bar

Display Bar Internals

The carriage has three full length shafts and a central shaft connected to the reset handle via a gear system which selects a gear depending on the rotation direction.

Each of the shafts is held in place with a retaining collar and a small grub screw in each end to apply end-float and be adjusted to allow free rotation of the shafts.

Dial Mechanism

The reset gear on the shaft has a small area where the cog teeth are removed and this matches with a corresponding tooth free area on the main reset cog connected to the handle. This allows the shaft to rotate a set amount for each counter-clockwise rotation of the reset handle and stop when the digits are in the correct zero location.

The 8 digit shaft has a similar system with the reset cog turning when the handle is rotated in the clockwise direction.

The 16 digit totals counter shaft was removed and each of the indicator numbers checked to ensure they rotated freely on the central shaft. Several were very tight and after applying a light oil, they rotated freely.

Cleaned and Oiled

My attention then turned to the gears on ends of each digit shaft and the central mechanism which selected the digits to reset. The gears where very tight to turn and after cleaning and adding fresh oil they turned freely but after reinstalling the 16 digit counter shaft I found that it would not reset more than once before jamming and not turning in either direction.

Finding the reset problems

After spending many hours trying to find a cause of the gear jamming problems and repeated disassembly and reassembling the mechanical components, the issue was tracked down to wear on the central reset gears.

Gear Wear

As each of the central reset gear cogs only has teeth on approximately 75% of its radius, it requires the teeth to engage perfectly with the cog on the digit shafts on each rotation so it can perform a full rotation and stop at the toothless area and pickup the first tooth on each cog on the next reset rotation. Due to wear on the end teeth this was not turning to the start position again, resulting in the gears jamming when trying to reset a second time.

Due to the age of this mechanical calculator, it is not possible to obtain spare parts. Replacement gears could be machined but at the present time I do not have a gear cutting machine, or a suitable lathe to machine replacement parts so for now it seems I will not be able to fully repair the machine.

It is still possible to manually reset the digits by lifting the movable carriage and turning each digit by hand but this restricts its ease of use.

Reassembled

This video link below shows a working Monroe model LN-160 which is similar to the L-200X and you can see how this calculator would have functioned when new. https://www.youtube.com/watch?v=KRiQk5301kg